The Continuing Saga of ex-Boston & Maine Coach No. 1246 (Part IV)

story by David Woodbury

The progress this year will bring to mind hiking in the White Mountains. For those of you who havenít done this, itís like this. The trail starts out from the parking lot at a modest grade and the trail is wide and easy. Almost immediately the grade steepens and the rocks begin. Each rock is different in height than itís neighbor and all of them are too high for comfortable walking. Itís like climbing an endless badly designed stair and never getting to the top. On top of that, the trees are close, large and close up over your head so that not only are you staring at the stairs in front of you, but if pause to look up, thereís nothing to see but leaves. You know not to pause or drink from your canteen since that makes starting up again almost impossible. Your legs ache and youíre sucking wind big time. Your companions are younger than you and theyíre way up the trail. You canít even hear them as they sprint ahead.

At long last as you peer ahead up the trail, you can see that thereís a bit more light ahead. This means that the grade is slackening if only you can make it that far. The trees are clearly smaller now and not so thick. You now arenít climbing those diabolical stairs, but rather walking on smoother ledge. If you look up, you can see the sky. Instantly, youíre out above the timberline. You can see to the sides and above and best of all if you look behind, you can see forever. The whole world spread out behind you. But look ahead and up the trail, you can see the summit. Itís still a thousand feet above you. A cloud drifts across the sun.

| Peeling back the plywood and plastic bit by bit gives a chance to install the outer stops and siding without too much exposure to a sudden rain storm. Notice the sawdust all over the window panes. Photo by Gary Luneau. |

This year started a little late. Before the end of winter I had roughed out blanks for the upper lights (half) of the eighty windows I needed to make for the year. When I got 1246, it had windows in it, but because it had been ďcombinizedĒ by the B&M in 1950, it didnít carry the full complement. Half the clerestory windows had been removed years ago and blanked over. I repaired and reglazed the remaining ones early in the project and had made and glazed new replacement clerestory windows earlier but hadnít installed them. Each main window consisted of two lights, an upper fixed light and a bigger raisable one on the bottom. Unfortunately, the windows in place were of no use even for patterns since they were of the wrong style. In addition, they were rotted out in places and good only for their glass. I spent quite a bit of time trying to salvage the mahogany for other projects only to find that a waste of time. Sooo, at the beginning of the year I had twenty clerestory windows all made and ready, but uninstalled, and had eighty bigger ones to make from scratch.

It was at this point that something came apart, me! I underwent a six-way heart bypass in late April. This set me back by a month so that in early June when I was able to get back to work, I was no further ahead than I had been in April. I had laid in a supply of mahogany that I thought was sufficient for the smaller upper lights during the winter. The originals were 7/8Ē thick and I was able to get mine at 13/16Ē through a contractorís over order at my local lumber supplier. The loss of 1/16Ē could be made up in the design of the window stops with out any inconvenience. The question was how to replicate the joint for sufficient strength and durability.

| This is where you begin. A pile of blanks waiting for the router, glue up, painting, glazing and finishing. Photo by David Woodbury. |

The original windows had a combination of rounded bead and mortise and tenon joint that I could find no equivalent for in any of the woodworking tool catalogues. There are plenty of router cutters to make raised panels and frames for cabinets, but fewer which could be adapted for glass. These left a joint that relied on gluing to end grain, not reliable and strong. The compromise I came up with was to use this joint and reinforce it with a hardwood dowel driven into the joint and glued. This would provide the functional equivalent of the missing mortise and tenon. With the plan in place, it remained to take the blanks for the first forty and finish them. This was not complex with the stile and rail cutter, but involved handling 160 pieces either once or three times depending on the piece. Then comes the glue-up. This requires a jig to make sure the corners are square with a series of wooden wedges to provide the clamping force. The jig I made would only handle two windows at a time. The glue manufacturer stated that clamping time would only a half hour, but I preferred to leave the windows clamped overnight. In theory, it would take twenty days to clamp them up and it about did. Of course, I could do other things to the glued-up windows as the process unfolded. Those other things included sanding, inserting the dowels and painting the outer surface with primer and two coats of exterior paint.

Then it came time to glaze. I had cut the glass I need for the upper lights from the old glass in the original bogus windows, but I needed quarter round stock to retain the glass once installed. I wanted quarter round in 5/16Ē radius to help make up for the 1/16Ē lost in the thickness of the main stock. This material isnít available in lumber stores much less in mahogany so I would have to make some. It isnít a terribly complicated process requiring only a table saw and a router with a 5/16Ē round over bit, but it isnít a fast one either. Back and forth between saw and router getting only two pieces of stock each time isnít much of a way to make real progress. This is especially obvious when you realize that you need four pieces for one window. Once you spread a bead of bedding compound and place the glass, then itís time to miter and fit the quarter round which you can do with your table saw and a fine blade. That only leaves nailing the quarter round without splitting it or worse breaking the glass with your hammer. The tool I found best is a mechanical inserter used by picture framers. It holds a small brad magnetically and by squeezing the handle, the brad is forced into the wood. Next is the finishing of the inner side. Staining, filling and varnishing with drying times and you can see where the summer is going.

| No, this isn't the final window color. It shows how wrong the hardware store can go tinting paint. It's perfectly useful as an undercoat. Photo by David Woodbury. |

Sometime in July, I was able to stack the upper lights in a corner and turn my attention to the main windows. The technique was the same, but the pieces were bigger. After modifying my jig to accommodate the bigger size, I still could only glue two at a time. It was deja vu all over again. I did have one problem to resolve before putting completed windows aside. The toilets had frosted glass windows. My glass supplier told me that frosted glass doesnít come from the factory that way, but that he has it frosted locally by a sandblaster at a monument works. Another alternative would be to go to my local craft store and use a product that crafters use to frost glass for small projects. When I went to the craft store and checked the product, the label warned against using it on large area and it was also quite expensive. I tried it anyway on a small area with good results, but when I tried it on a full pane, I couldnít get an even smooth effect. After a couple of attempts, I went to the monument works. They did a good, even job, but the overall effect wasnít as fine or pleasing as the chemical.

Now that the windows were finally done and stacked against the wall, I had to face the task of building the stops to keep the windows in. The outer stops were originally of ash screwed to the piers. They were of a sort of wrap around design inletted to accept, hold and fix the upper sash and to fit into a slot in the underside of the letter board as well as fit snugly against the slope of the window sill. All told it was a rather complex shape, calling for many steps with router and table saw. The plus side was that I had to make only eighty of them, half rights and half lefts. In addition I would have to make forty strips also of ash to go across the top of the window and seal that side. There was nothing for it but to get started. Luckily I had anticipated the need several years ago and asked a neighbor if I could cut a large ash on his property. He graciously assented and the deed was done. A local sawmill sawed and planed it up and for the past four years, it had been lying in my barn. It was no picnic to cut and some of it had a grain that wasnít straight enough so there was a small amount of waste. Thatís where the stove kindling comes from. After a day or so, I had a supply of blanks made up and it was time to open up the plywood which had been covering the windows for the past four years. One last task lay ahead. I needed some siding for the wide piers of the same size as the siding below the belt rail that I had put on years earlier. I wasnít impressed with the behavior of the original yellow poplar and wanted to try a different product. I settled on MDO, an exterior smooth paintable plywood. It advertised as millable and durable to the elements if painted. The sign industry uses it extensively. It isnít too expensive, but weighs a ton. I milled up a couple of sheets and painted the raw edges as recommended. It milled up well without the voids found in ordinary plywood. It nailed on more easily than the poplar and made a good appearance. Only time will tell if itís truly as durable as advertised.

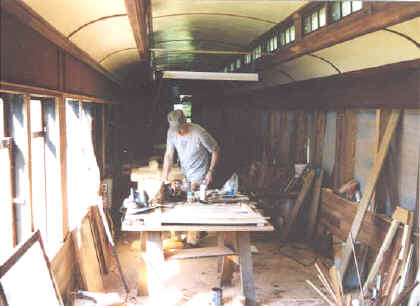

| This is the interior after clean up. It's gone from dark and gloomy to light and even warm on sunny days. Photo by David Woodbury. |

When I pulled off the plywood , the interior of the car went from gloomy and dark to light in an instant. I only pulled off as much plywood as I could replace with windows at any one time so the transformation wasnít complete right away. In fact it took me another month or so to install the windows on one side.

During the summer while windows were gluing or paint drying, I tried repairing water damaged veneer. The panels between the windows and between the clerestory windows were of a mahogany veneer with a line of marquetry inlay. I had torn out and replaced those too badly damaged, but about half were salvageable if patched. New veneer was easily available as was the underlayment for those places where the damage went below the veneer itself. The only trouble was that Pullman had used a premium figured veneer which while still available was both very expensive and not available in large enough sheets for my purposes. Under the circumstances, I used the regular veneer and by making a pattern and cutting out the damaged areas, I could make a decent repair that after staining and filling would look good.

| This is repaired veneer. Modern mahogany veneer isn't as highly figured as the original. When stained and filled, it blends in well enough. The patch in this picture is not yet stained. Photo by David Woodbury. |

After finishing the first side, the fall was well along and I wasnít interested in having the second side open when the first snow fell. I packed up my scaffolding and put it away with the plywood in place on the second side. I still had to make the inner stops for the windows I had installed. They were not too complex except for routing a groove for the curtain hardware. Not that I have any curtains or expect to ever find any of the right kind, but you never know. These I affixed with eight oval head wood screws each for appearance and proceeded to stain the new interior work.

| Toward the end, the clutter and mess got overwhelming. One day I had to stop work and take a couple of trips to the landfill. Photo by Gary Luneau. |

The snow and cold weather held off long enough to let me get this far, but at last I had to lay off and find something else to do. On sunny days, the interior can warm up quite nicely thanks to the glass on the west side. This allows me to stain although itís not warm enough to fill or varnish. With luck, I can finish staining this winter and be ready to set up my staging on the second side in April. I should be done with the windows in about two weeks and can then get to work on interior finish, saloon doors and finally a finished floor. The party comes in the fall.