Professor Tross was tasked with solving pandemic staybolt breakage problems in the German locomotive fleet starting in 1937. One cause of this problem was the flexibility of the the mudring portion of the boilers.

Germans typically made the mudrings 1" to 1-1/2" high. North American practice was to make the mudrings square up to 4" thick. The formal North American name was the Foundation Ring. This forced all the expansion of the firebox sheets upwards and outwards. The German practice did not provide this rigidity.

Note mudring thickness from German cross sectioned locomotive from Wikipedia:

From the paper "Tross New Knowledge Locomotive Rear Boiler" from Matt Janssen's website:

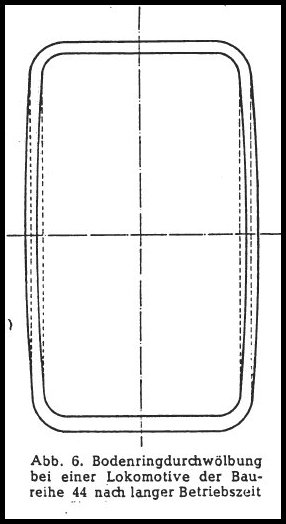

Ilustration No. 6 clearly indicates this as an example of the bulging of the 44 class locomotives. See information of the German Class 44 from Wikipedia here.

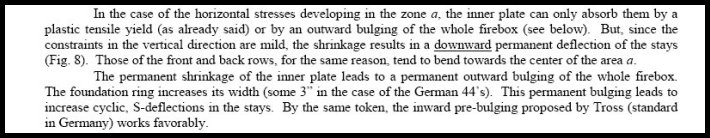

From the translation and the scientific writing style of Tross, the comment "was only 80 mm" is obtuse in it's meaning. In a translated paper by Porta, provided by Matt Janssen, the meaning is clearly defined as a 3" spread (appx. 80 mm) of firebox sides in the German 44 Class 2-10-0 locomotive of which almost 2000 were produced.

My personal question is "what would be the reaction, if on a morning inspection, the firebox of Frisco 1630 or Strasburg 90 showed a 1-1/2" outward bulge along the mudring?"