| It is currently Thu May 22, 2025 11:46 pm |

|

All times are UTC - 5 hours [ DST ] |

German Firebox Bulging

Moderators: Rick Rowlands, tomgears, Randy Hees

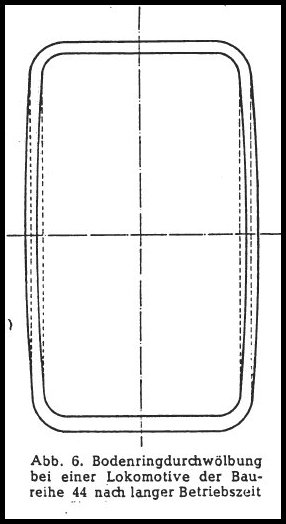

|

Page 1 of 2 |

[ 26 posts ] | Go to page 1, 2 Next |

|

| Author | Message | ||

|---|---|---|---|

| M Austin |

|

||

|

Joined: Sat Feb 05, 2005 1:05 am Posts: 481 |

|

||

| Kelly Anderson |

|

||

|

Joined: Tue Sep 14, 2004 7:52 am Posts: 2477 |

|

||

| M Austin |

|

||||

|

Joined: Sat Feb 05, 2005 1:05 am Posts: 481 |

|

||||

| jim templin |

|

||

|

Joined: Sat Aug 21, 2004 11:31 pm Posts: 295 Location: TEXAS |

|

||

| Tim Botti |

|

||

|

Joined: Wed Aug 25, 2004 4:18 pm Posts: 216 Location: Pittsburgh PA |

|

||

| M Austin |

|

||||

|

Joined: Sat Feb 05, 2005 1:05 am Posts: 481 |

|

||||

| Tim Botti |

|

||

|

Joined: Wed Aug 25, 2004 4:18 pm Posts: 216 Location: Pittsburgh PA |

|

||

| M Austin |

|

|||||

|

Joined: Sat Feb 05, 2005 1:05 am Posts: 481 |

|

|||||

| Robby Peartree |

|

||

|

Joined: Wed Aug 25, 2004 11:16 am Posts: 767 |

|

||

| Dave |

|

||

|

Joined: Sun Aug 22, 2004 7:19 am Posts: 6464 Location: southeastern USA |

|

||

| Mike Tillger |

|

||

|

Joined: Sun Aug 22, 2004 11:06 am Posts: 543 Location: NE PA |

|

||

| M Austin |

|

||

|

Joined: Sat Feb 05, 2005 1:05 am Posts: 481 |

|

||

| Mike Tillger |

|

||

|

Joined: Sun Aug 22, 2004 11:06 am Posts: 543 Location: NE PA |

|

||

| Bruce Mowbray |

|

||

|

Joined: Wed Sep 01, 2004 9:07 pm Posts: 17 Location: Northeastern PA |

|

||

|

Page 1 of 2 |

[ 26 posts ] | Go to page 1, 2 Next |

|

All times are UTC - 5 hours [ DST ] |

Who is online |

Users browsing this forum: Google [Bot], Majestic-12 [Bot] and 158 guests |

| You cannot post new topics in this forum You cannot reply to topics in this forum You cannot edit your posts in this forum You cannot delete your posts in this forum You cannot post attachments in this forum |